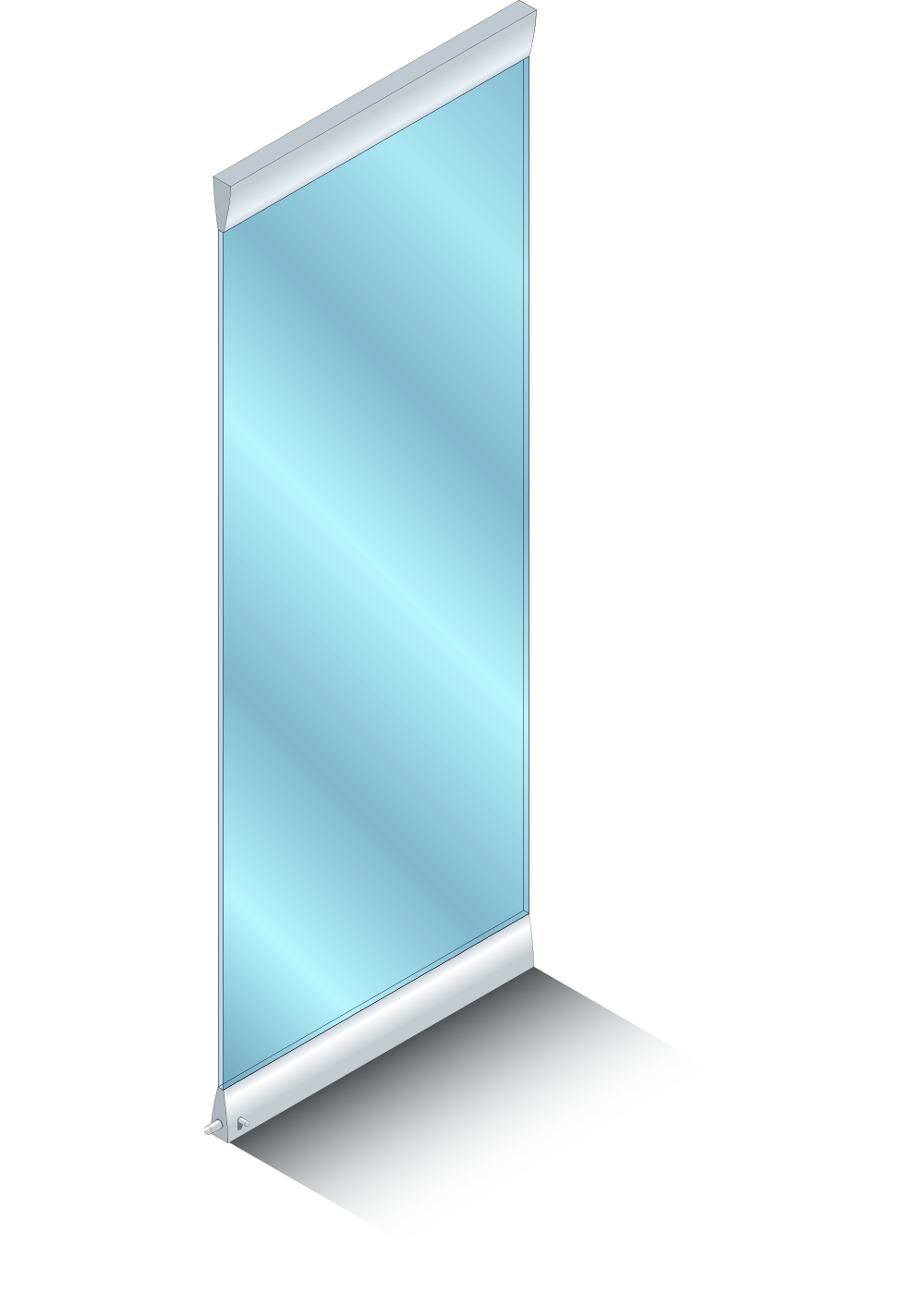

Glass walls are excellent aesthetic dividers, offering many applications. The elements move on a top track via a Twin Point system, two carriage assemblies with system being able to stack in a variety of configurations (see stacking arrangements). The panels are stacked according to requirements and when deployed are locked into position with foot operated shoot bolts.

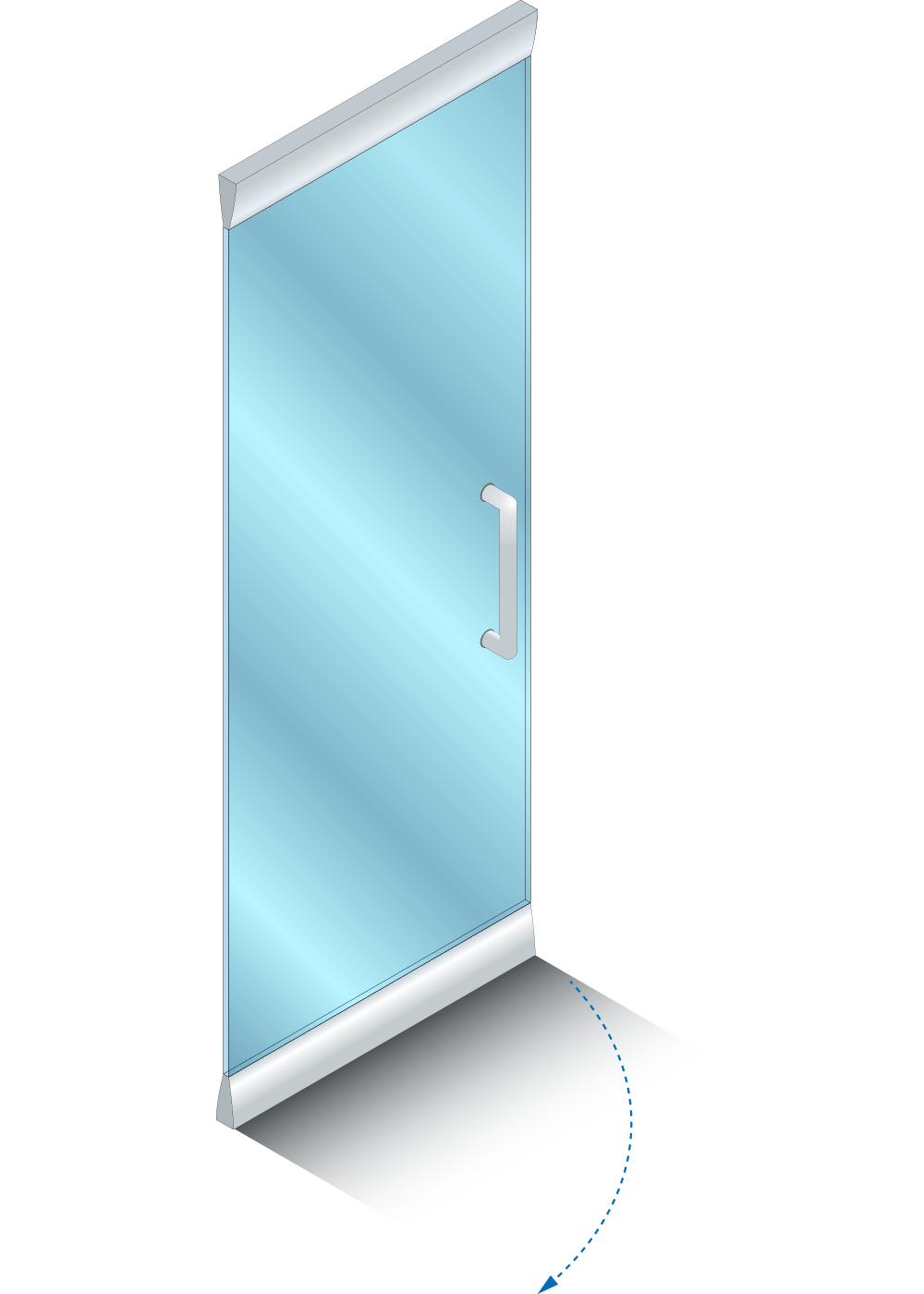

There is also a hinged version available which runs along our single point track. One carriage assembly at the top of alternate panels, stacking centrally on main line of track.

Available with a fixed pass door which is opened back whilst the panels forming the division may be stacked back to the system pass door.

The top and bottom profiles are of satin anodised aluminium. The glass is hardened safety glass 10mm or hardened laminated glass 5+5mm.

The maximum height of the elements is 3500mm. Taller ones are available but by having an extra portion added to each panel to a maximum of 1000mm.

Suspension & Support:

Top Hung Twin Point configuration via supportive head track, no floor track necessary. Folding Single Point system also available (see stacking details in next section).

Specification Sound Reduction Range:

Non acoustic.

Operation:

Manual.

Weight Range:

Up to 35 Kg per m2.

Maximum Height:

Up to 3,500 mm.

Maximum Panel Width:

Up to 1200mm Panel Width.

Panel Thickness:

10mm Toughened Safety Glass.

Maximum Opening Width:

Varies according to system height and configuration.

Fire Ratings:

N/A

Glass Finishes:

Clear as standard. Frosted & Tinted also available (manifestation, or custom vinyl graphics available upon application)

Panel Clamp Extrusions (Top & Bottom):

Satin Anodised Aluminium (SAA) as standard, Electrostatic Powder Coating (EPC) also available in all RAL colours.

Track Options:

Twin Point aluminium track in Electrostatic Powder Coated (EPC) white, made to bespoke configurations to client specification and design.

For Folding Version Only – Single Point aluminium track in

Electrostatic Powder Coated (EPC) white.

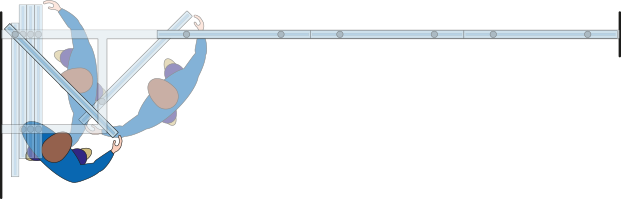

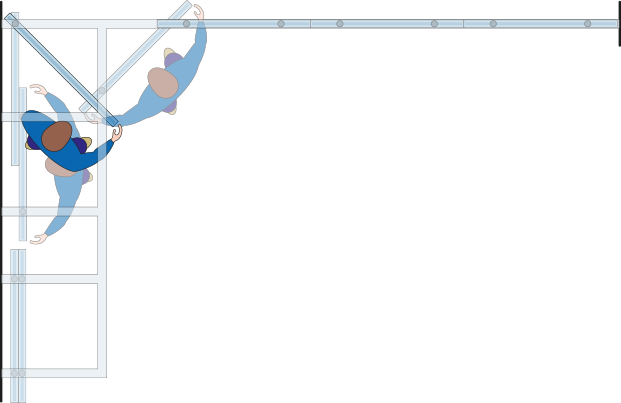

Each panel runs along the head track on two carriages. Panels do not turn freely but are controlled by both carriages to positively line up with the stacking area.

Similar to the M2 stacking layout but there is a branch track between the main line and first stack leg. The branch track length can be adjusted to suit site conditions.

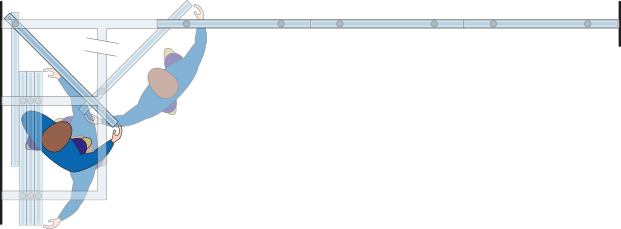

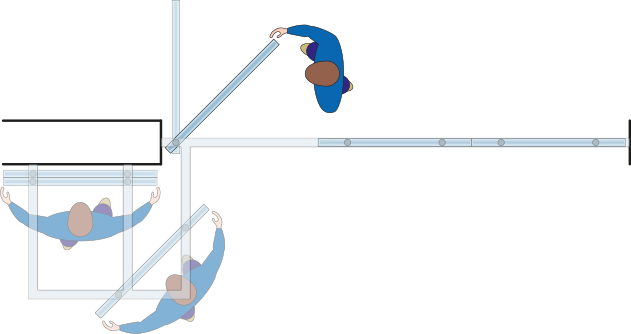

Dual remote stacks can be used to maximise room space and reduce depth of panel stacks.

Another variation of the dual stack layout, this time using a double stack offset to one side.

Tailored arrangements can be agreed with our technical team.

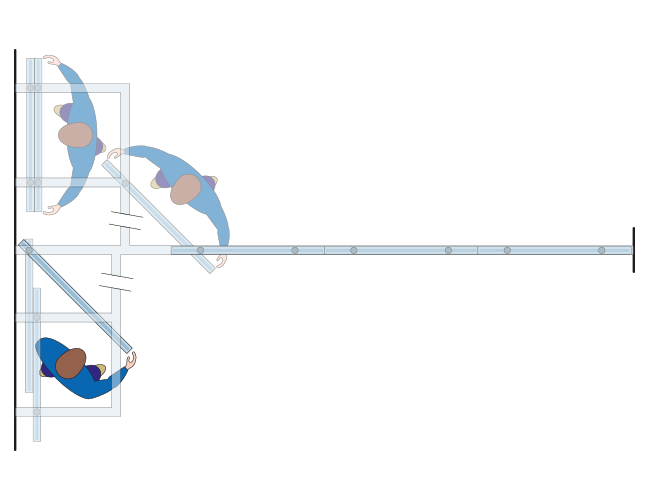

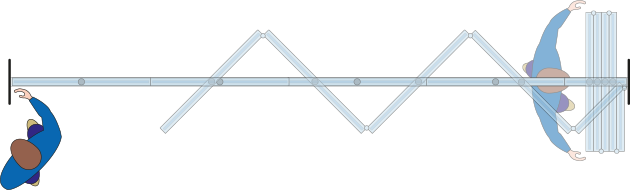

Each panel runs along the head track on a single. central carriage. Each panel is hinged to the next and are stacked at one end centrally to the track. The system pulls out from one side to close off the opening, with the lead panel being an active pass door.

Permenantly hinged